Fingerprint recognition technology has advanced significantly, with each packaging process tailored to meet specific performance requirements. This guide outlines the current methods of fingerprint recognition chip packaging, emphasizing the role of adhesives in enhancing reliability and efficiency.

1 Fingerprint Recognition Chip Packaging Processes

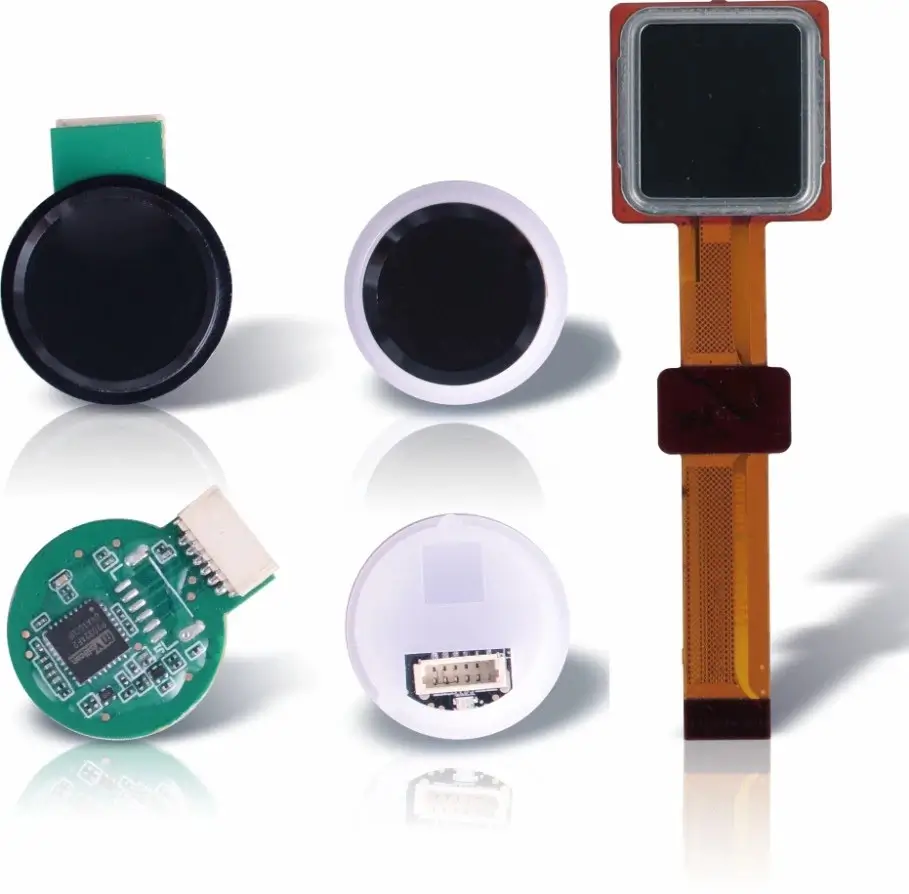

1.1 Wirebonding Process

Wirebonding remains the most prevalent method for packaging fingerprint recognition chips. This process involves connecting metal wires, which are subsequently embedded in a molded material to create a flat interface between the chip and the protective cover. Although molding can increase the chip’s thickness and potentially impact recognition accuracy, for hole-in-display solutions—where direct finger contact with the sensor occurs—a satisfactory user experience can still be achieved. Manufacturers often prefer wire bonding for mid-to-low-end products due to its cost-effectiveness and mature technology.

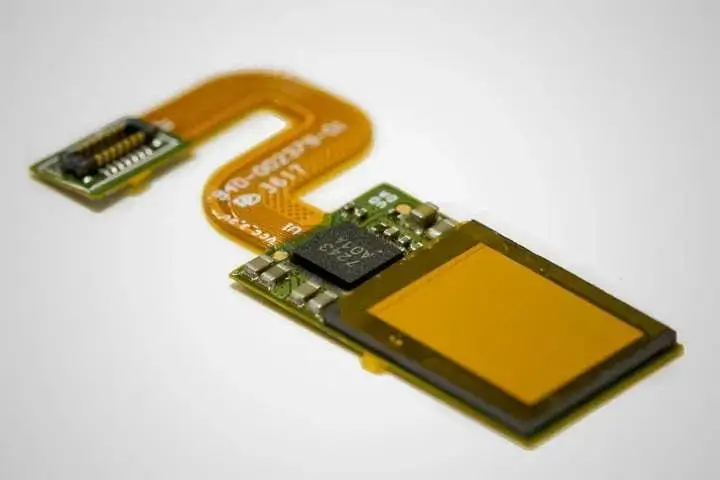

1.2 TSV Packaging Process

Through Silicon Via (TSV) technology enhances the effective sensing area of fingerprint recognition chips while reducing the overall thickness of the module. It is predominantly used in high-end applications, such as front-facing and blind-hole capacitive UnderGlass fingerprint recognition, where performance is prioritized. As full-screen displays gain popularity, the demand for TSV packaging may stabilize as devices increasingly adopt rear-facing solutions.

1.3 SiP Packaging Process

System-in-Package (SiP) technology is gaining traction due to its ability to reduce size, thickness, and power consumption while enhancing performance. Compared to traditional PCB integration, SiP offers higher flexibility and improves manufacturing efficiency, making it a compelling choice across various applications, including mobile devices, wearables, and IoT devices. As the trend shifts toward capacitive UnderGlass solutions, the combination of TSV and SiP packaging will become increasingly important for manufacturers seeking advanced solutions.

2 Fingerprint Recognition Module Packaging Processes

The packaging of fingerprint recognition modules typically involves four configurations: front-facing press, back-facing press, front-facing slide, and back-facing slide. The two primary manufacturing approaches are panelized structures and small board cutting, with the panelized method currently being the more prevalent choice. The typical assembly process includes:

- Module positioning on a fixture.

- Component encapsulation.

- Chip underfill application.

- Curing.

- Silver paste dispensing.

- Epoxy adhesive dispensing.

- Metal ring placement.

- Fixture-based pressure curing.

3 Fingerprint Recognition Packaging Materials

3.1 Metal Ring/Frame Packaging Materials

3.1.1 Conductive Bonding

To bond metal frames and Flexible Printed Circuit (FPC) substrates, silver paste is typically used. Care must be taken to avoid overspill, which could cause short circuits during the pressing process. Effective discharge paths enhance the sensor’s integrity and establish electrical connections with the device housing.

Vsiko provides two types of epoxy conductive adhesives designed for high-speed dispensing, featuring excellent adhesion to silver, copper, and gold.

3.1.2 Insulating Bonding

A gap of 0.1mm beneath the metal ring/frame requires sufficient adhesive application to secure bonding without overflow. Low-temperature curable epoxy adhesives are recommended for these applications.

Vsiko offers a one-component heat-curable epoxy adhesive, ideal for bonding various substrates, including thermally sensitive components requiring low-temperature rapid curing.

3.2 Driver Chip Packaging Materials

Underfill adhesive is crucial for securely encapsulating driver chips on the FPC. Vsiko offers epoxy underfill adhesives featuring low viscosity and rapid curing, minimizing stress from thermal expansion mismatches.

3.3 Fingerprint Recognition Main Chip Packaging Materials

To ensure precision, adhesive overflow for the fingerprint recognition chip is strictly controlled, with underfill adhesives used for encapsulating all four corners of the chip.

Vsiko provides an epoxy underfill adhesive suitable for both CSP and BGA processes, designed to form a defect-free layer upon curing.

3.4 Sensor and PCB Packaging Materials

When positioning sensors and peripheral components, minimal warping is crucial. A low-temperature curable epoxy adhesive, with a minimum thickness of 0.20mm, is recommended for secure assembly.

3.5 Cover and Holder Packaging Materials

The fingerprint module’s sink depth is approximately 0.5mm, requiring gap-filling adhesives to ensure seamless bonding between the bezel and glass.

Vsiko’s one-component acrylate UV adhesive is ideal for this application, providing optical-grade properties and slight elasticity to handle thermal variations and mechanical stress.

3.6 Cover Plate and IC Packaging Materials

To facilitate optimal interaction between the user’s finger and the sensor, the cover plate requires a large opening. Adhesive bonding must accommodate low curing temperatures and precise wire control amid ongoing miniaturization challenges.

Vsiko’s colorless and transparent epoxy adhesive is specifically formulated for such applications, offering strong adhesion, thermal shock resistance, and excellent flow characteristics.

Conclusion

Effective adhesive use in fingerprint recognition module packaging significantly contributes to the performance and reliability of these devices. As technologies evolve and the demand for miniaturization and efficiency grows, collaborative efforts in adhesive material development and packaging processes will play a pivotal role in advancing fingerprint recognition systems.

If you have any questions about adhesive selection and usage, please feel free to contact us. Our team of experts has extensive experience and can provide you with free consultation services.