1. Development History of Intelligent Robotic Dogs

- In 1968, General Electric (GE) designed a quadruped robot named the Walking Truck for infantry, which required manual control to operate its valve for limb movement.

- In 1992, Boston Dynamics was established, and research on quadruped robots began.

- In 2003, Sony’s fourth-generation AIBO robotic dog was launched with basic interactive features.

- In 2005, Boston Dynamics developed BigDog, capable of carrying 150 kg of cargo across complex terrains.

- After 2015, Boston Dynamics introduced products like Spot, significantly enhancing stability and agility.

- In 2019, YuShu Technology released the Aliengo quadruped robot.

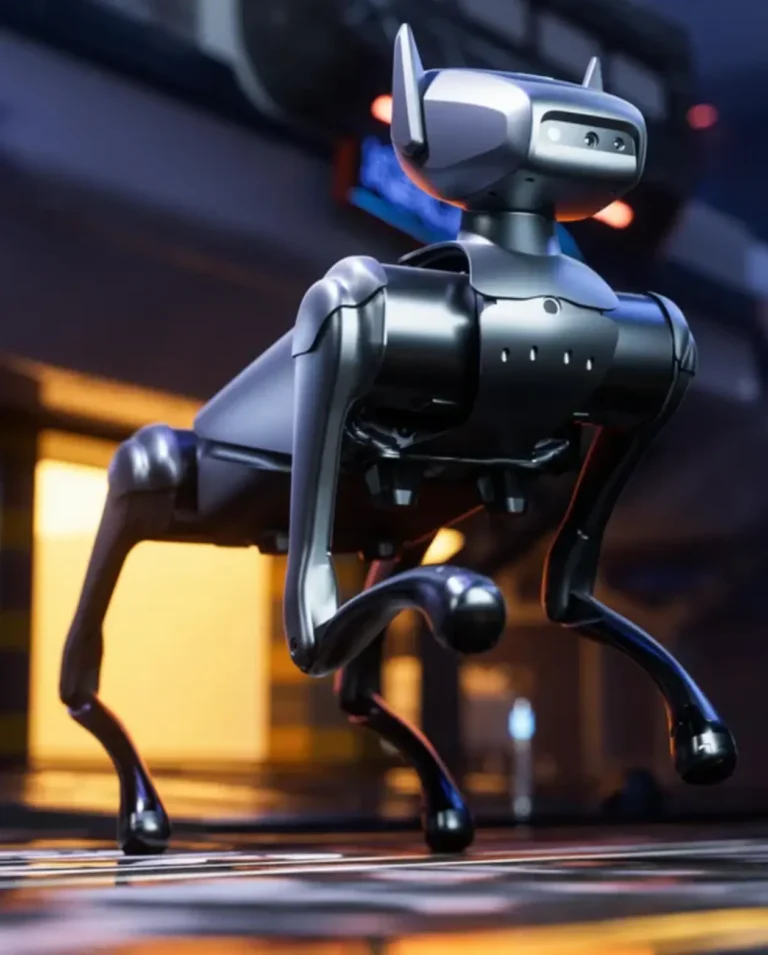

- In 2021, Xiaomi launched its first bionic quadruped robot, the “CyberDog”.

2.Technical Principles of Intelligent Robotic Dogs

- Drive Technologies

Hydraulic drive offers powerful force and is suitable for harsh environments and heavy loads.

Electric drive allows for precise control and low noise but has limited load capacity.

Pneumatic drive is cost-effective and lightweight, though it lacks precision.

Electro-hydraulic drives combine the advantages of the above but come with higher costs and maintenance challenges.

- Perception Technologies

This includes sensing the surrounding environment through cameras, Lidar, and other sensors, using deep learning algorithms to recognize, classify, and localize objects.

- Motion Control Technologies

Flexible movement completion of designated tasks is achieved through autonomous planning and path-finding algorithms. The coordination of leg design and motor operation, along with leverage principles, enables the execution of various movements.

3.Adhesive Materials for Intelligent Robotic Dogs

- AI Chip Conductive Adhesive

VPS395 is an epoxy resin conductive adhesive known for its excellent workability and outstanding thermal and electrical conductivity. It provides an effective thermal pathway for bare silicon chips, addressing heat dissipation challenges and the impact of adhesive layers on semiconductor electrical performance. It is suitable for various lead frame packages like SO and QFN.

- MCU/SoC Bottom Fill Adhesive

VP5810 is specifically designed for bottom filling of MCUs/SoCs in robotic dogs. The complete process involves: flux application → chip placement → heating and reflow → flux cleaning → flow filling → heating and curing.

- Lidar Adhesive

Targeting the assembly of Lidar bearing sleeves and prisms, VP3410VM is an epoxy resin material with silica-filled adhesive, featuring a low-halogen formulation. It utilizes a dual curing mechanism of UV and heat, allowing for rapid curing under ultraviolet light or low temperatures. It offers low stress, low curing shrinkage, and excellent moisture and oxygen isolation for long-term reliability.

If you have any questions about adhesive selection and usage, please feel free to contact us. Our team of experts has extensive experience and can provide you with free consultation services.