Camera Compact Module, abbreviated as CCM, is an image input device that is closely related to our social life. Photography, videography and videography are all relied on it, and are widely used in automotive electronics, mobile phones and computers, medical imaging and security monitoring.

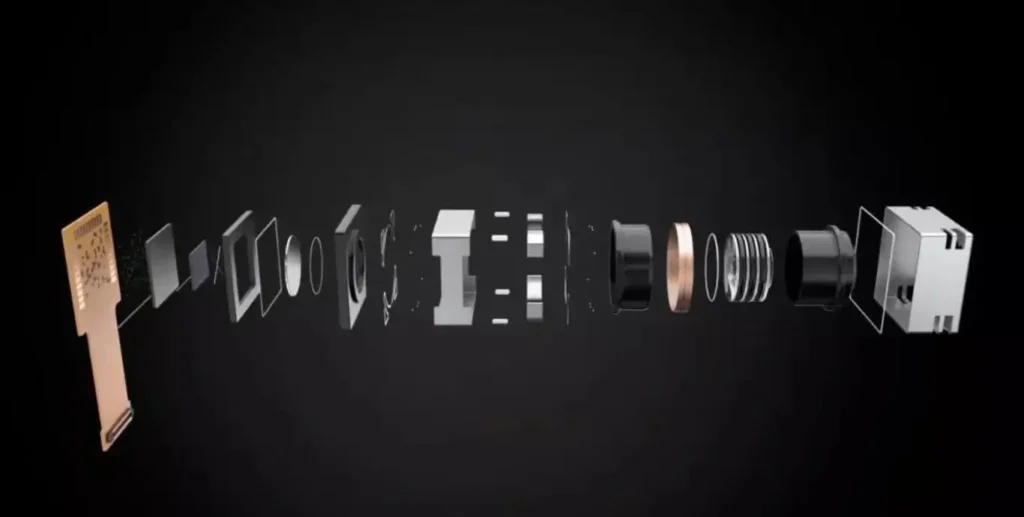

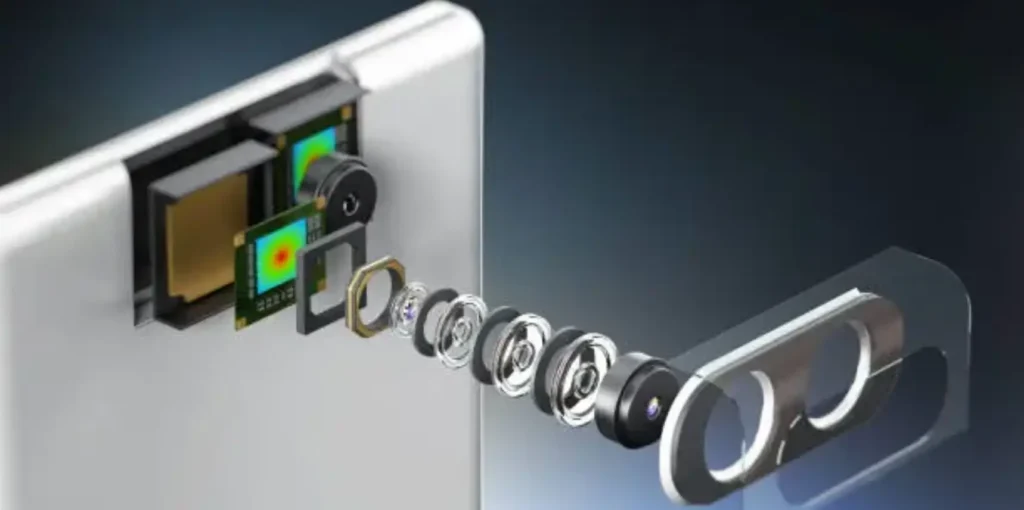

The camera module is small in size, but the internal structure is very complex. For example, the camera module components of a mobile phone include: lens, sensor, image processing chip, focus motor, filter, FPC/PCB, etc. The packaging technology includes Chip Scale Package, Chip On Board, ChipOnFle X, FlipChip, etc., the glue used includes black, red, transparent, shaking, flowing, low-temperature curing type, ultraviolet irradiation curing type, etc.

1.Structure of the camera module

1.1. Lens (LENS)

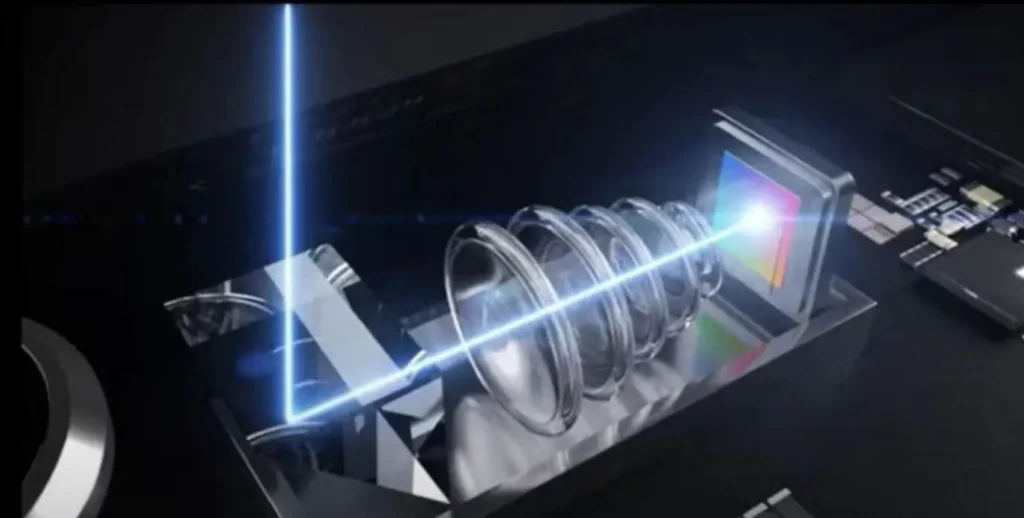

A group of plastic or glass and plastic combined lenses are precisely designed to receive light signals, correct and filter stray light, and converge light signals on the photosensitive device.

1.2. Voice coil motor (VCM)

A device that controls the stretching position of the spring sheet by changing the DC current of the motor coil in the permanent magnetic field to drive the lens movement and autofocus function.

1.3. IR filter

A filter device that can filter the near-infrared part of the image sensor’s detection spectrum to avoid red imaging.

1.4. Sensor (SENSOR)

A camera module core component that converts external light into electrical energy, and then converts the obtained image signal into digital signal output through the analog converter on the chip, and then performs a series of operations such as light analysis, color restoration, and impurity removal. It mainly includes CCD and CMOS.

1.5. Flexible circuit board (FPC)

A device that connects components and other circuits.

2.Camera compact module packaging process

The more popular packaging processes for camera modules include CSP (Chip Scale Package), COB (Chip On Board), COF (Chip On Flex), FC (Flip Chip), etc. Among them, COB and CSP packaging processes are two mainstream electronic assembly technologies, which are favored by mobile phone camera module manufacturers. The COB packaging process is to first bond the photosensitive chip to the substrate with gold wire, and then bond the lens and bracket to the substrate. The CSP packaging is to first fix the photosensitive chip to the substrate with SMT, and then fix the lens and bracket to the substrate. The FC process is currently only used by Apple, and the electrical process faces down, which greatly reduces the thickness of the module.

3.Camera module packaging materials introduction

3.1.Lens and lens mount fixing glue

Low shrinkage optical grade UV glue, low temperature fast curing glue and UV heating dual curing glue are mainly used to fix the lens and lens mount. Among them, UV heating dual curing glue is used in the active alignment process, referred to as the AA process, that is, the AA equipment detects and locates the semi-finished product and then actively aligns it to complete the assembly closed loop.

3.2.Lens and lens barrel fixing glue

Mainly use fast-curing UV glue, which requires resistance to cold and hot shocks and reliability under high temperature and high humidity conditions.

3.3.Filter fixing glue

Mainly use UV curing glue and low-temperature fast-curing glue to bond and fix the filter to the lens base.

3.4.Lens holder bracket and substrate fixing

Mainly use low-temperature fast-curing glue and UV heating double-curing glue to bond, seal and protect the flexible circuit board and the substrate.

3.5.Flexible circuit board reinforcement glue

Mainly use low-temperature fast-curing glue or UV glue to bond the iron shell to increase sealing and conduction current.

3.6.Sensor and substrate fixing glue

Mainly use low-temperature fast-curing glue to bond the photosensitive chip, and use bottom filling glue to enhance the high reliability of the chip.

3.7.Voice coil motor packaging glue

Mainly use low-temperature curing glue to bond the coil and bracket of the voice coil motor and fix the magnet and shrapnel. Use conductive silver paste to bond, seal and protect the spring, motor terminal and side reinforcement in the voice coil motor.

4.About vsiko products

After years of analysis, research and horizontal comparison of camera modules, packaging processes and materials used by popular brands, vsiko has developed a series of camera module packaging glues to meet customers’ process requirements.

If you have any questions about adhesive selection and usage, please feel free to contact us. Our team of experts has extensive experience and can provide you with free consultation services.